Water medication systems

Increasingly, pork production systems around the world are using drinking water as the delivery mechanism for a variety of nutritional and health related products. These products can range from acidifiers and probiotics at weaning to vaccines to antimicrobials to nutritional supplements, etc. throughout the growth process.

Delivery of these products via the drinking water system most often relies on a pump and mixing chamber to incorporate these materials into the drinking water. In the US, most medicators are based on a fixed ratio of 1 part stock solution per 128 parts drinking water.

With the increased usage of water delivered products has come an increase in the risks associated with these delivery systems. The following are common mistakes made by US producers in using water as the delivery mechanism for a variety of products.

Many products, especially vaccines, require that the pigs consume the product within 4-6 hours of reconstitution. Recent data from Iowa State University suggests that 100% of weaned pigs will visit a nipple drinker within a 4-6 hour time period beginning at 8 am. Thus, timing of delivery of the product to the drinking water is of critical importance if all pigs in a population are to receive an adequate amount of the product.

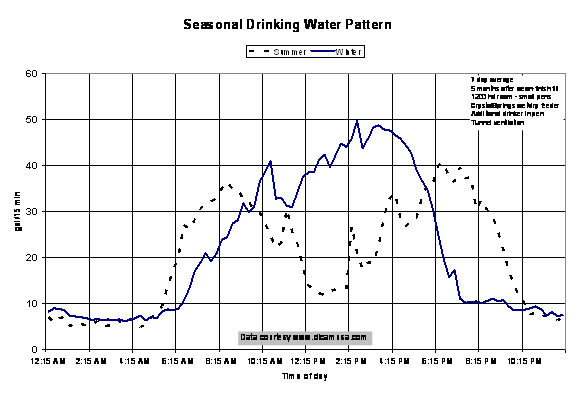

Figure 1: Effect of season on 24-hour water usage pattern in a 1200 head wean-finish facility 5 months after weaning in central Nebraska. Data courtesy Dicamusa.com

In thermo-neutral conditions, both feed and water usage generally begin increasing around 6 am in the morning, with a mid-morning peak around 10 am, followed by the day’s peak in disappearance at 2-3 pm. By 6 pm, both feed and water intake have returned to a relatively low level. There is very little feed or water intake during the night. Drinking water disappearance, and by association feed disappearance, is minimal during late evening and early morning hours.

If pigs are grown to slaughter in warm conditions (summer conditions in much of the upper Midwest), these patterns change. Feed and water intake now begins at approximately 4 am, with the morning peak at 8-9 am. This morning peak is followed by a mid-day decline in feed and water disappearance, with a resumption in intake in the early evening hours. Even in these conditions, there is limited drinking water usage during late evening or early morning hours.

In North America, commonly used water medicators are often rated at a capacity of up to 26.5 litres (7 US gal)/minute. In almost every instance, they are connected to water lines in the facilities that have a capacity of 21 liters (5.5 gal) per minute (19 mm/3/4” inside diameter piping). This suggests that the sizing of the water delivery pipes in the facility are the limit to water flow. However, it is quite common to see water medication devices connected to water delivery lines with 13 mm (1/2”) diameter hoses, which have a capacity of only 9.5 liters (2.5 US gal)/minute. A common complaint by producers who make this mistake is ‘my pigs don’t like the medicine in the water because water intake always decreases when I water medicate’. The real cause of the decline in drinking water is the restriction in water flow associated with the water medication device connection.

In North America, commonly used water medicators are often rated at a capacity of up to 26.5 litres (7 US gal)/minute. In almost every instance, they are connected to water lines in the facilities that have a capacity of 21 liters (5.5 gal) per minute (19 mm/3/4” inside diameter piping). This suggests that the sizing of the water delivery pipes in the facility are the limit to water flow. However, it is quite common to see water medication devices connected to water delivery lines with 13 mm (1/2”) diameter hoses, which have a capacity of only 9.5 liters (2.5 US gal)/minute. A common complaint by producers who make this mistake is ‘my pigs don’t like the medicine in the water because water intake always decreases when I water medicate’. The real cause of the decline in drinking water is the restriction in water flow associated with the water medication device connection.

A second common mistake is a stock solution reservoir that is too small. Many producers assume that water usage is relatively stable throughout a 24-hour period. If the pig’s drinking water usage is 4 litres (1.1 US gal) per day and there are 1000 pigs in the facility, the total stock solution required at 1:128 dilution is 31.25 litres (8.3 US gal). If the stock solution reservoir is filled twice daily, this suggests that a 16 litre (4.2 US gal) capacity reservoir is adequate. In reality, almost 70% of the drinking water is consumed from 6 am to 4 pm. If the reservoir is filled at 7 am and 5 pm, the capacity of the reservoir needs to be at least 22 (5.8 gal) litres or there is a risk that the reservoir will be empty prior to the next recharge, resulting in pigs drinking water that has no stock solution added.

Many producers fail to account for the impact of pressure regulators on water flow. If the incoming water line pressure is 275 kPa (40 psi) and a regulator is used to lower the line pressure to 140 kPa (20 psi), water flow is reduced to 71% of what it was at the original pressure. This suggests that sizing of water lines is even more important than many producers think.

Water filters are often installed in delivery lines to deal with sediment issues associated with the on-site well, etc. In some instances, the location of the filters makes them very difficult to routinely flush or clean, while in others, a routine of regular maintenance is not planned for.

Water filters are often installed in delivery lines to deal with sediment issues associated with the on-site well, etc. In some instances, the location of the filters makes them very difficult to routinely flush or clean, while in others, a routine of regular maintenance is not planned for.

Finally, don’t overlook the water meter as a flow restrictor in the water line. Many swine facility contractors install water meters with 16 mm (5/8”) orifices that have 19 mm (¾”) NPT connectors. These meters are generally $50-75 cheaper than meters with larger orifices.

Photo Captions:

Medicator-1 – Two medicators for 2400 wean-finish pigs with 125 litre (33 gal) stock solution reservoir

Medicator-2 – Water medicator rated at 26.5 litres (7 gal)/minute incorrectly connected to 19 mm (3/4”) inside diameter piping with 13 mm (1/2”) washing machine hose.

.