Group Sow Housing Resources

Posted in: Pork Insight Articles, Prairie Swine Centre, Press Releases, Welfare by Ken Engele on November 23, 2018 | No Comments

Group Sow Housing & Management Seminar

Posted in: Pork Insight Articles, Prairie Swine Centre, Press Releases by Ken Engele on October 2, 2018 | No Comments

| View the full program here 2018 Group Sow Housing & Management Seminar Brochure |

|

Enrichment for sows: increasing positive behavior

Posted in: Pork Insight Articles, Prairie Swine Centre by Ken Engele on October 1, 2018 | No Comments

On Canadian farms, interest in enrichment has grown recently due to changes in the Code of Practice requirements, stating that ‘Pigs must be provided with multiple forms of enrichment… to improve the welfare of the animals through the enhancement of their physical and social environments.’ This change, along with increasing adoption of group housing for sows led a team of Canadian researchers, directed by Dr. Laurie Connor at the University of Manitoba, to study how best to provide enrichment to sows in groups.

Most studies on enrichment have looked at grow-finish pigs because this is the stage when most damaging behaviours appear, such as tail biting or flank sucking, and the effects can be devastating. A few studies have been done on sows, with the general conclusion that feeding fibrous materials such as straw or hay is best: pigs are highly attracted to items that are both manipulable and consumable, and for feed-restricted sows the increase in gut fill is an added bonus.

Mitigating Barn Deterioration

Posted in: Pork Insight Articles, Prairie Swine Centre by Ken Engele on | No Comments

When we look across the Canadian pork industry it becomes apparent that due to the age of most facilities a large percentage will need to be replaced or renovated over the next few years – as most buildings average between 20-30 years old. The majority of production units are completely enclosed utilizing a negative pressure ventilation system to maintain pig comfort. In order to reduce heating costs during winter months ventilation is generally turned down to a minimum ventilation rate. The combination of minimum ventilation and, in some areas high winds, causes exhaust air to recirculate within the facility leading to poor air quality. This in turn increases deterioration due to increased exposure to moisture and corrosive gases. This project set out to determine Canadian specific strategies for decreasing barn deterioration.

Understanding the interaction between nutrition and pig health

Posted in: Pork Insight Articles, Prairie Swine Centre by Ken Engele on | No Comments

With new legislation eliminating the use of in-feed antibiotics for growth promotion in Canada and increasing consumer pressure to reduce antibiotic use in animal agriculture, it is critical that we develop alternatives to antibiotic use in order to maintain animal performance and health during immune challenge. An increased understanding of the interaction of nutrition and animal robustness (i.e., the ability to cope with an immune challenge), therefore, will be a key component in efforts to replace and/or reduce antibiotic use. Specifically, nutrition-based alternatives to antibiotic use need to be identified.

Pigs are continuously exposed to microbial pathogens and immune-stimulatory antigens that negatively impact animal productivity. Pigs exposed to immune challenge, without exhibiting any clinical signs of disease, show reduced appetite and growth and less efficient use of nutrients compared to healthy animals. Previous studies have estimated a reduction in lean growth of 20-35% and feed efficiency of 10-20% in growing pigs at sub-clinical levels of disease (Williams et al., 1997; Le Floc’h et al., 2009). This decrease in performance can have a substantial impact on profitability of producers. Stimulation of the immune system alters protein and amino acid metabolism and utilization, with amino acids redirected from growth towards supporting the immune response. Of the amino acids, glutamine, arginine, threonine, and aromatic and sulfur amino acids are of particular importance as precursors for synthesis of many critical components of the immune response (Reeds and Jahoor, 2001). It is thought that provision of these amino acids may be important for improving pig response and growth performance during times of stress and disease challenge.

Gestation Housing Systems: Auditing Best Management Practices: Part 4

Posted in: Pork Insight Articles, Prairie Swine Centre, Production by student on August 3, 2018 | No Comments

Author: Ken Engele, BSA

Reference: Centred on Swine Fall 2018, Volume 24, Number 2

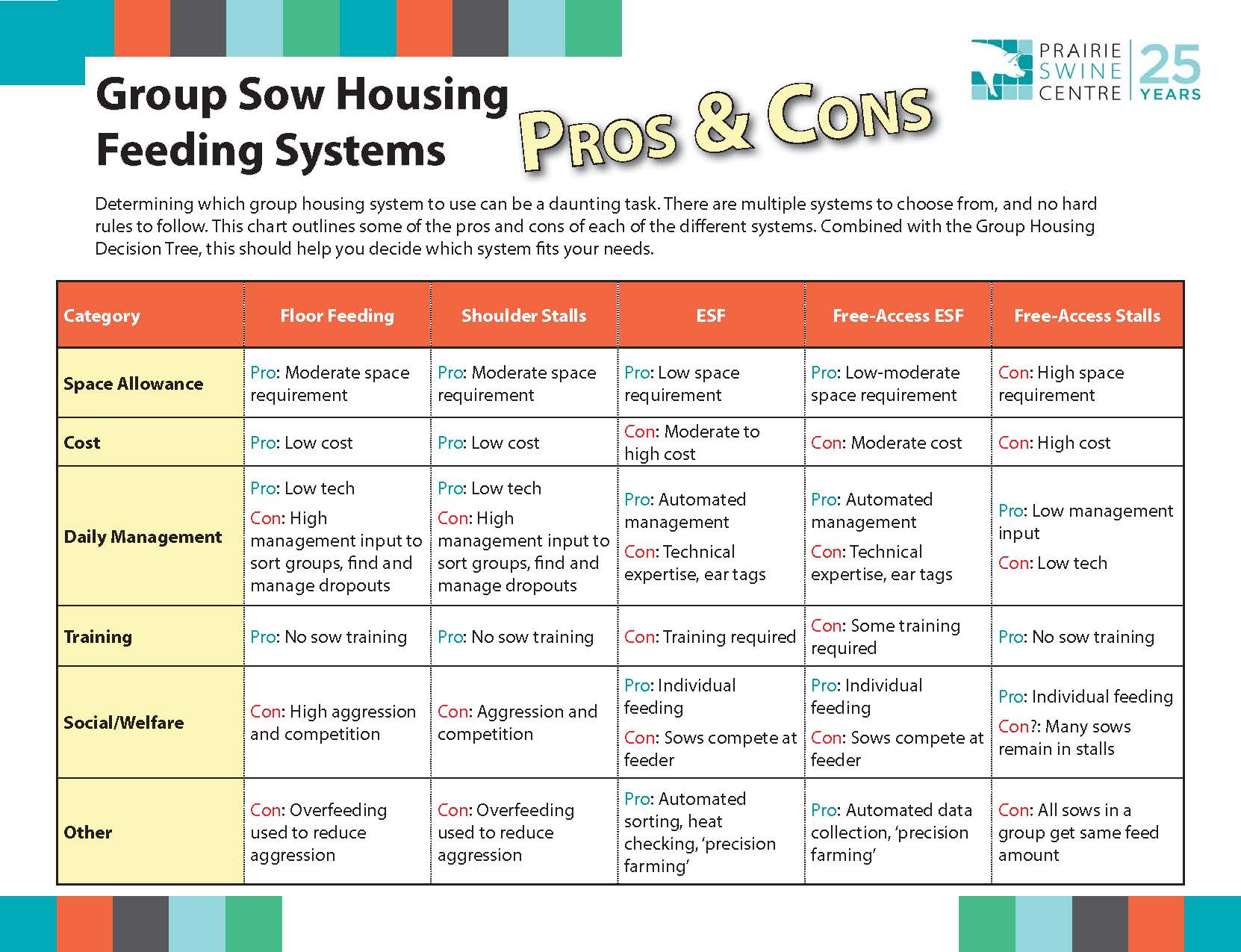

Summary: At the forefront of swine production is the change to group sow housing. As a means to provide more information to producers and aid them in making the conversion by the 2024 deadline this article focuses on the best management practices in relation to many gestation housing systems.

Nine of the 24 facilities that were audited incorporated group sow housing into their practice. It has been estimated that nation wide 15% of sows are being housed in group housing.

Of the facilities that were audited who are currently housing their sows in a group housed setting two thirds of them have chosen to incorporate a non-competitive feeding system. For those who have chosen to utilize a competitive feeding system have typically done so due to the cheaper cost associated with conversion.

Electronic sow feeding systems are an effective measure for data collection and a herd management tool. An opportunity that electronic feeding systems generally offer is the ability to feed multiple gestation diets through the sow herd. Research has displayed the need for parity specific diets due to amino acid and energy requirements.

For producers who are looking to make the transition to group sow housing there are many resources that they can access. They can go to the website: www.groupsowhousing.com to find a variety of information.

Demonstrating Water Conservation

Posted in: Pork Insight Articles, Prairie Swine Centre, Production by student on | No Comments

Author: Ken Engele, BSA

Reference: Centred on Swine Fall 2018, Volume 24, Number 2

Summary: Research has demonstrated that even when the nipple drinkers are properly adjusted in a finisher barn the pigs will waste 25% of the water. Water wastage on commercial farms from nipple drinkers has been reported to be as high as 40-60%. A recent audit determined that approximately 2/3 of nipple drinkers provide water volumes that exceed the requirement of the pig, sometimes doubling the required volume.

When considering water conservation, barn evaluations determined that the use of a drinking trough save 60% of water, mainly due to reduced water wastage. The water trough did not impede the performance of the pig.

Potential economic benefits were calculated for a commercial farm that implemented water troughs. Over a 24 week period, water disappearance from water troughs was 20% less than from traditional nipple drinkers. For one year and 170 pigs the difference in water disappearance with a trough set up would be 89,250 L. As well considering the cost of manure disposal (assuming that the excess water ends up in the pits) there would also be a savings of $343 for 170 pigs.

| Advantages | Disadvantages |

| Significant water savings

Reduced manure volume Installed with off-the-shelf components Improved biosecurity – less traffic to the barn site |

One more thing to wash – corners

Higher potential contamination of water in the trough |

The producer who installed the troughs for the purpose of this study will continue to use the troughs due to the advantages of reduced water usage and decrease manure volume.

Washing Procedures: Auditing Best Management Practices – Part 3

Posted in: Pork Insight Articles, Prairie Swine Centre, Production, Uncategorized by student on | No Comments

Author: Ken Engele, BSA

Reference: Centred on Swine Fall 2018 Volume 24, Number 2

Summary: In a swine barn the top usage of water is allocated to animals drinking as well as for the purposes of cleaning. Decreasing water utilization within facilities will aid in developing a more sustainable environment and lower the cost of production.

One aspect that is included in many washing protocols is pre-soaking. Many facilities pre-soak a room prior to pressure washing, however this is not always necessary as pressure washing in a fully slatted floor can be completed without pre-soak. Pre-soaking the room increases the utilization of water. However, when considering partially slatted floors it was evident that an it took longer to wash the room if it was not pre-soaked.

Nozzle selection can also have a significant influence on water utilization. Research has identified that when considering water conservation the use of conventional nozzles leads to the lowest volume of water used, as well as time spent washing those rooms.

Transitioning to Loose Sow Housing

Posted in: Pork Insight Articles, Prairie Swine Centre, Production, Swine Innovation by student on July 25, 2018 | No Comments

Author: John Van Engelen

Summary:

John Van Engelen describes the phases of his conversion for stall housing to group housing for sows.

Group Sow Housing Across Canada: What Have We Seen

Posted in: Pork Insight Articles, Prairie Swine Centre, Production, Swine Innovation by student on | No Comments

Author: Doug Richards and Dr. Jennifer Brown

Summary:

This project had Doug Richard and Dr. Jennifer Brown traveling across the country to visit and tour barns with producers that had group sow houses or were going to put it in.

The following is a brief tour of what they saw:

New Brunswick: 1200 sow operation, since 2004. Saw the benefits of genetic selection over 12 years, well oiled machines. Benefit of culling for genetics. Has a shower unit.

Quebec: 850 sow operation, solid bedrooms with partitions. Renovation. Has solid floors in the middle.

Quebec: 600 sow. Renovation. Utilized Gestal operation.

Ontario: 1400 sow operation, new build, each pen has 17-18 sows. Has to go off of parity and size, “gilts in their first parity cause a lot of problems”. This was the only competitive feeding system. There are not partitions. Feed in the morning.

Ontario: 650 sow operation. Renovation. Fully slated barn.

Ontario: 1800 sow. Partitions, sows like to have something against their back and their side.

Ontario: 220 sow.

Ontario: 100 sow Organic, 23 pigs per pen. Allows the pigs outside. Farrowing crate is 81 sq feet and only closed for four hours.

Manitoba: 3000 sow operation. Never loss production. Rented another bar. Then once the one side was completed they moved the sows from the one side to the other and started construction on the other half. The sows that were send out to the rented barn where not brought back to the property they were culled.

Manitoba: 650 operation. Put in a training unit. This is one thing that was lacking in most of the systems.

Saskatchewan: 600 sow operation. The gilt barn is totally slatted, sow barn has some solids.

Alberta: 275 sow, conversion. Have to work with the manufacturer to see what you can do.

Takes different staff training to work with these animals as they do not respond the same way that stall housed sows do.