Incorrect temperatures found in 36% of semen storage units

Posted in: Uncategorized by admin on July 14, 2011

A recently published study of semen storage temperatures carried out in Ontario showed that inappropriate temperatures were recorded in 36% of on-farm storage units. The authors, Drs. Beth Young, Cate Dewey and Robert Friendship, noted that producer errors, including adding warm semen to the unit, poor unit maintenance, and poor temperature control, were the most frequent causes of incorrect temperatures.

“Semen is cooled during storage to decrease the metabolic rate of the sperm,” explained the authors. “When semen is stored at temperatures of more than 20°C, sperm maintain a high metabolic rate with rapid energy consumption and by-product production, resulting in a short shelf life. Temperature fluctuations can also impact stored semen quality, and it has been suggested that for each 2°C to 3°C fluctuation in semen temperature, the shelf life of that semen is decreased by one day, they noted. Because boar sperm are particularly temperature sensitive, appropriate on-farm semen storage is a critical factor in achieving good AI results.”

For the survey, a sample of 27 Ontario swine farms was visited and on each farm, an air-temperature-logging device, set to record air temperature at 1-minute intervals, was placed in the farm’s semen storage unit. A log sheet was taped to each storage unit, and producers were asked to record the date, time, and reason each time the storage unit door was opened. The type of storage unit (refrigerator-type or cooler-type) was also recorded.

Storage unit temperatures that fell outside the temperature range of 15°C to 20°C for ≥ 40 minutes were considered unacceptable. Storage-unit temperatures that fluctuated by ≥ 2°C for ≥ 40 minutes were also considered unacceptable.

In one herd, semen was stored in two separate storage units, so temperature data was collected from a total of 28 storage units. The average number of times the storage units were opened was 2.8 times per day, with the minimum zero times per day and the maximum eight times per day. The most commonly reported reason was to remove semen doses for breeding (Table 1).

Table 1: Reasons recorded by producers for opening their semen storage units, reported as a percent of 166 door-opening events*

| Recorded reason for opening storage unit | Percent |

| Removing semen doses for breeding | 56.0 |

| Returning unused semen after breeding | 19.3 |

| Loading fresh semen into storage unit | 6.0 |

| Turning semen doses | 6.0 |

| Adding frozen gel packs to storage unit | 4.2 |

| Removing doses for semen evaluation | 2.4 |

| Checking thermometer in storage unit | 1.8 |

| Removing-replacing drug bottles in storage unit | 1.8 |

| Counting semen doses | 1.2 |

| Returning gel packs after breeding | 1.2 |

* Results reported for 26 storage units on Ontario farms visited between May and October, 2004. Door-opening events were recorded for 72 hours.

Unacceptable semen storage temperatures were recorded in 10 of 28 (36%) of the storage units examined. Nine of these 10 storage-unit temperatures were considered unacceptable because temperatures were outside the 15°C to 20°C range for ≥ 40 minutes. In eight of the nine units in which temperatures fell outside the 15°C to 20°C range, temperature fluctuations of > 2°C were also recorded. The type of storage unit used was not associated with inappropriate semen storage temperature. However, a polystyrene picnic cooler used by one farm performed very poorly.

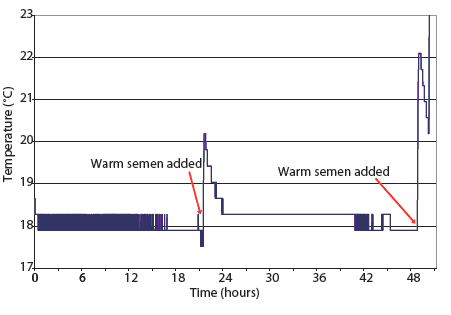

In seven of the 10 problem storage units (70%), the unacceptable temperatures appeared to have been triggered by specific events recorded by the producers. In three cases, unacceptably high temperatures occurred when warm, fresh semen doses were put into the storage unit (Figure 1).

Figure 1: Temperatures recorded by an air-temperature-logging device at 1-minute intervals in a semen storage unit in which temperatures exceeded 20°C and fluctuated by > 2°C when warm semen was placed inside the unit.

Poor maintenance of the storage unit was the cause of unacceptable storage temperatures in two cases. In one, the storage-unit door did not close properly and occasionally opened unexpectedly. This happened once during the temperature-recording period. The temperature in the storage unit fell to the air temperature of the barn (13°C to 14°C) and the temperature remained low for approximately 10 hours until the door was closed. In the other case of poor maintenance, a storage unit with a frayed electrical cord failed while the temperature logger was in place. In less than 2 hours, the temperature in the storage unit rose to 22.5°C. The problem was noticed and ice packs were added to the storage unit, which caused the temperature to drop rapidly to 8.6°C. Approximately 4 hours after the storage unit first failed, a new electrical cord was installed and the temperature in the storage unit stabilized within the appropriate range.

In two instances, poor temperature regulation of the unit caused unacceptable storage temperatures. In one case, the thermostat was set too high and the storage unit consistently maintained a temperature > 23°C. In the other case, a polystyrene picnic cooler with ice packs was used as a semen storage unit. Each time an ice pack was added, large temperature fluctuations occurred (up to 4°C), and the temperature fell below 15°C for approximately half of the temperature-recording period.

In this study, more problem storage units produced temperatures that were too cool than temperatures that were too warm. Boar sperm is extremely sensitive to cold shock, which is one reason the use of frozen boar semen is not a practical alternative for the swine industry.

Nine of the 10 problem units experienced temperature fluctuations of > 2°C. Variation in storage temperature forces sperm to re-adjust their metabolic activity in order to adapt to changes in their thermal environment. This depletes nutrients and buffer in the extender and diminishes semen quality.

Most problems with storage temperature in this study were directly attributable to the actions of the producers. This suggests that more emphasis on producer education in proper storage-unit management and maintenance is needed, say the authors of the study.

Most problems with storage temperature in this study were directly attributable to the actions of the producers. This suggests that more emphasis on producer education in proper storage-unit management and maintenance is needed, say the authors of the study.

Thirty percent of the unacceptable storage temperatures were attributable to adding still-warm semen to the storage unit. If there is cooled semen in the storage unit when the warm semen is placed inside, the higher air temperature caused by this action may have a negative impact on the quality of the cooled semen. Some means to avoid placing warm semen in the storage unit include allowing the semen to cool to below 20°C in an area of the barn cooled by a fan or air conditioner, or to have two separate units, one for cooling semen and one for storing semen once it is cooled, suggest the authors.

Because poor maintenance was identified as a cause of unacceptable storage temperatures, producers should be encouraged to regularly maintain their storage units. Storage units should be routinely inspected and damaged parts should be repaired or replaced. Units should also be cleaned regularly to prevent dust from building up around the air circulation system, which may cause inefficient operation or overheating. Daily temperature monitoring should also be a part of routine storage-unit maintenance. Simple high-low thermometers are an inexpensive, easy and effective method for producers to monitor temperatures inside their semen storage units, concludes the report.

Reference: Young B, Dewey CE, Friendship RM. Prevalence and causes of inappropriate temperatures in on-farm semen storage units in Ontario. J Swine Health Prod. 2008;16(2):92–95.

Take home messages:

|

Photo: Semen fridge-1 – A study carried out in Ontario showed that inappropriate temperatures were recorded in 36% of on-farm storage units